Machining Services You Can Trust

“A state-of-the-art quality program, innovative equipment, and the latest technologies guarantee the customer the finest quality products that can be manufactured.” – Henry Braddock III, Founder

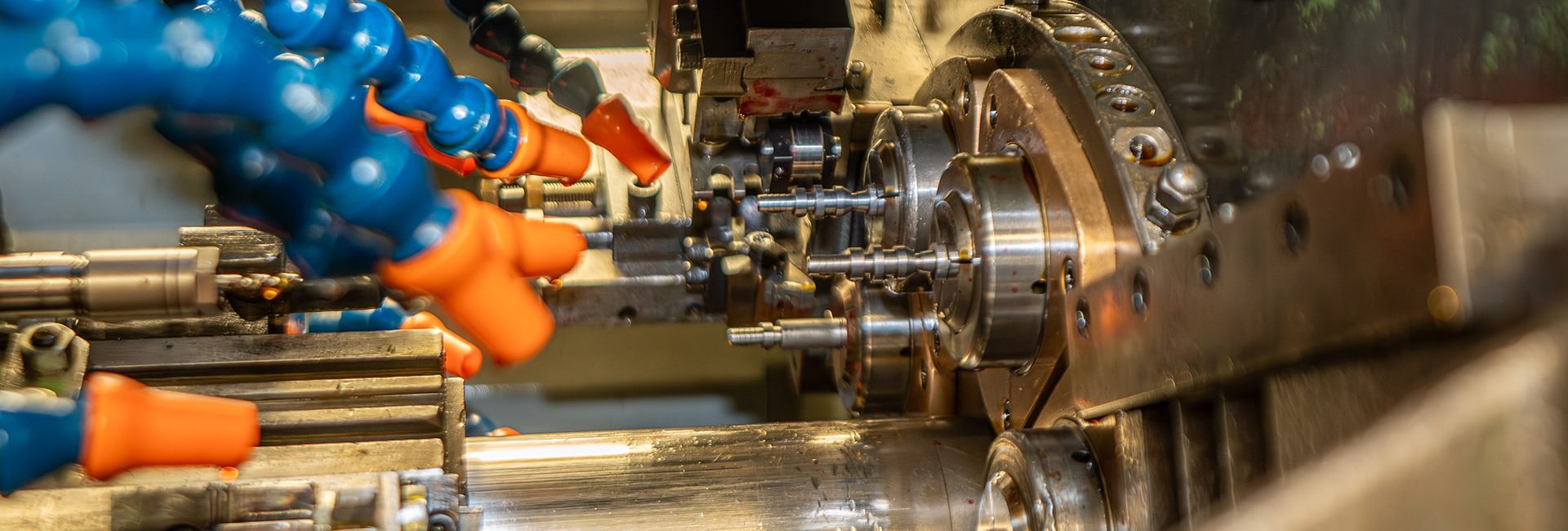

St. Joe Tool Company provides a wide range of machining services to clients throughout the United States. With over 60 Screw Machines, several CNC cells, EDM’s. Centerless Grinders, Cold-Headers, Plasma Cutters, Assembly Lines, Custom-Built Machinery, and Custom-Built Tube Mill Lines, complete with built-in quality controls, and fitted with custom tooling from creative solutions.

St. Joe Tool will build the machine around your part and continue to work relentlessly to accomplish your goals. The growth of St. Joe Tool is greatly attributed to the valuable relationships they have built with customers and engineers, along with the problem-solving added value that their customers have grown to count on. Working closely with your engineers, St. Joe Tool can solve any challenges and take your product from prototype to any volume of production you require.

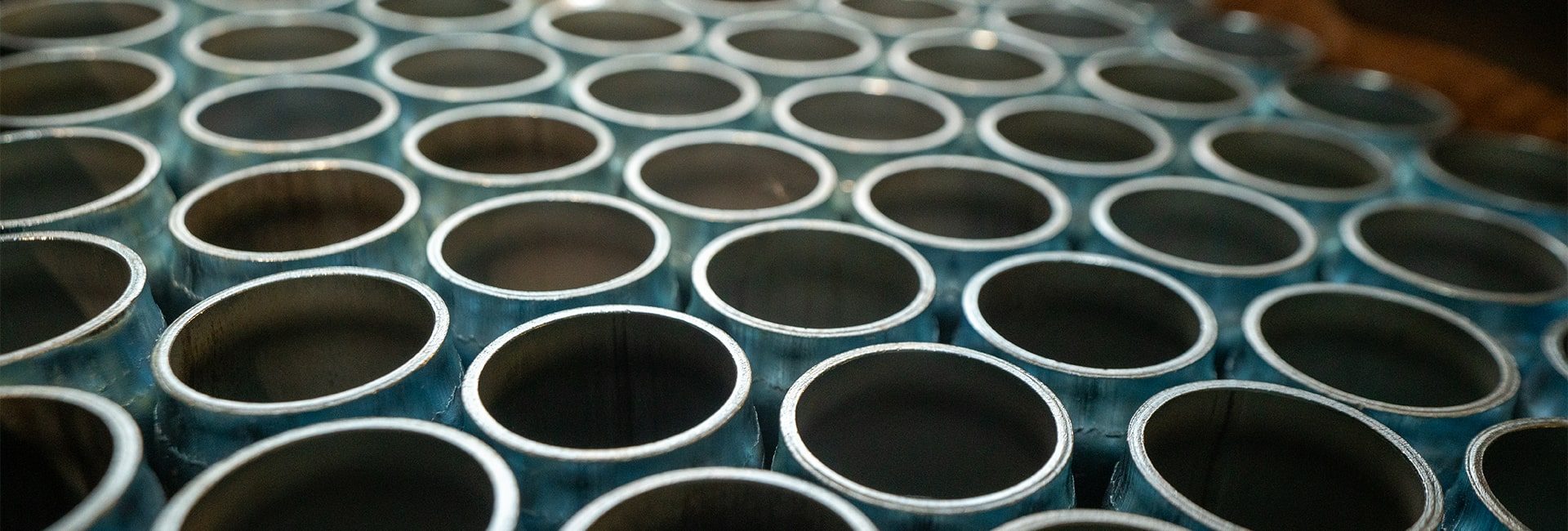

Production Machining

St. Joe Tool Company has the capability to provide high-volume production to keep your operation running smoothly and efficiently. Whether you need our assistance designing parts to meet your needs and specifications or you just need us to complete the production machining for parts you have already been using long-term, you can count on our team to complete the machining with a focus on quality to ensure that you are able to maintain your high standards.

Parts Assembly

At St. Joe Tool Company, we offer parts assembly to fit together components, streamlining your process of creating a finished product. Using specialized tools and machinery, we can ensure that your parts are properly assembled and ready to go the second they arrive at your facility. This maximizes efficiency and keeps your business running smoothly and profitably. We assemble parts for companies in a number of different fields and can develop effective solutions for the unique challenges you face.

Four Plants of Manufacturing & Design

Our facility features four plants staffed with experts who can handle your needs from the design process on through production and inspection.

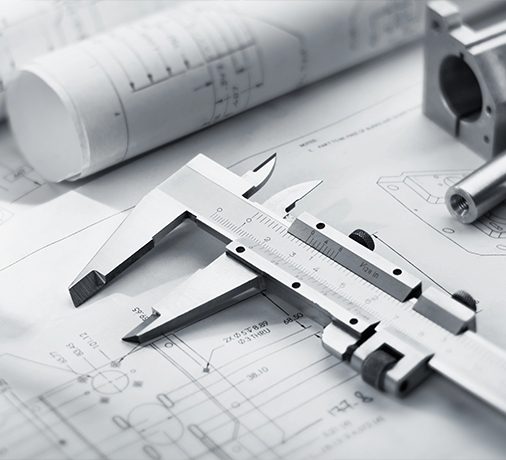

Design

We can provide you with design assistance to create custom parts or prototypes for new projects or older projects that require discontinued or hard-to-find parts.

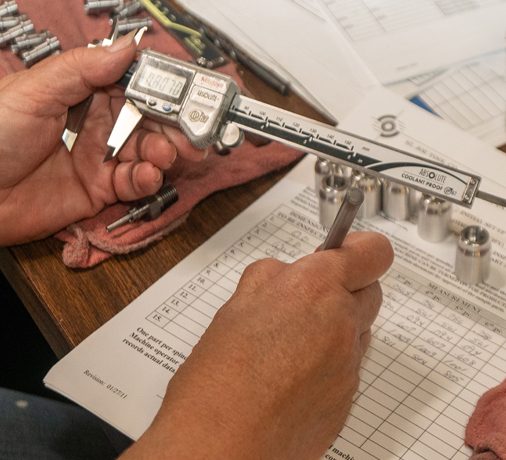

Quality

We combine custom built measuring tools, Statistical Process Control (SPC), as well as the latest technology for fast, and precise measurements of parts to ensure the tightest tolerances in the industry.

Inspection

We take the time to inspect the parts before, during, and after the production process to identify any potential issues before costly mistakes have been made.

60 Years In Business

For 6 decades, we have worked diligently to build and maintain strong business relationships with our clients. With a focus on quality and continuous improvement, our team is well-respected throughout the country and North America for delivering timely, effective solutions with a high standard of quality that few shops can match.